- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Kia Corporation Unveils EV4 & Concept EV2 at EV Day in Spain

- Latest: Volklec Announces Plans to Open a Dedicated 10GWh UK Battery Gigafactory

- Latest: Mercedes-Benz Begins Solid-State Battery Road Tests

- Latest: BMW Unveils Sixth-Generation BMW eDrive Technology for the Neue Klasse

- Latest: Recovering Critical Battery Materials - Ace Green Recycling CEO

Creating Lighter, Stronger & More Advanced Materials for Mobility - NAWA Technologies' CEO Antoine Saucier

Adrian Smith

- Jun 06 2023

NAWA Technologies has developed nano-led technology that can be applied to all mobility sectors, through advanced composites, hydrogen fuel cells and storage tanks, and advanced batteries. The pioneering French company recently named Antoine Saucier as CEO. He joined after holding senior roles at PSA Peugeot Citroën, Valeo and TomTom.

"I am a car enthusiast and have always been interested in the latest technology. That passion for all-things automotive overlaps with my desire to make positive change in the industry via pioneering innovation," Saucier tells Auto Futures.

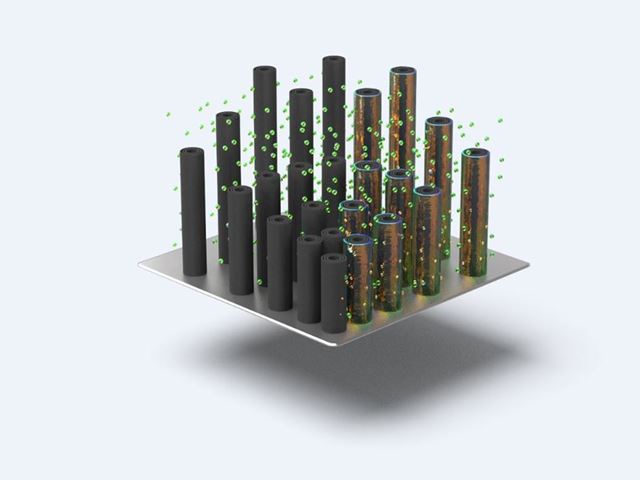

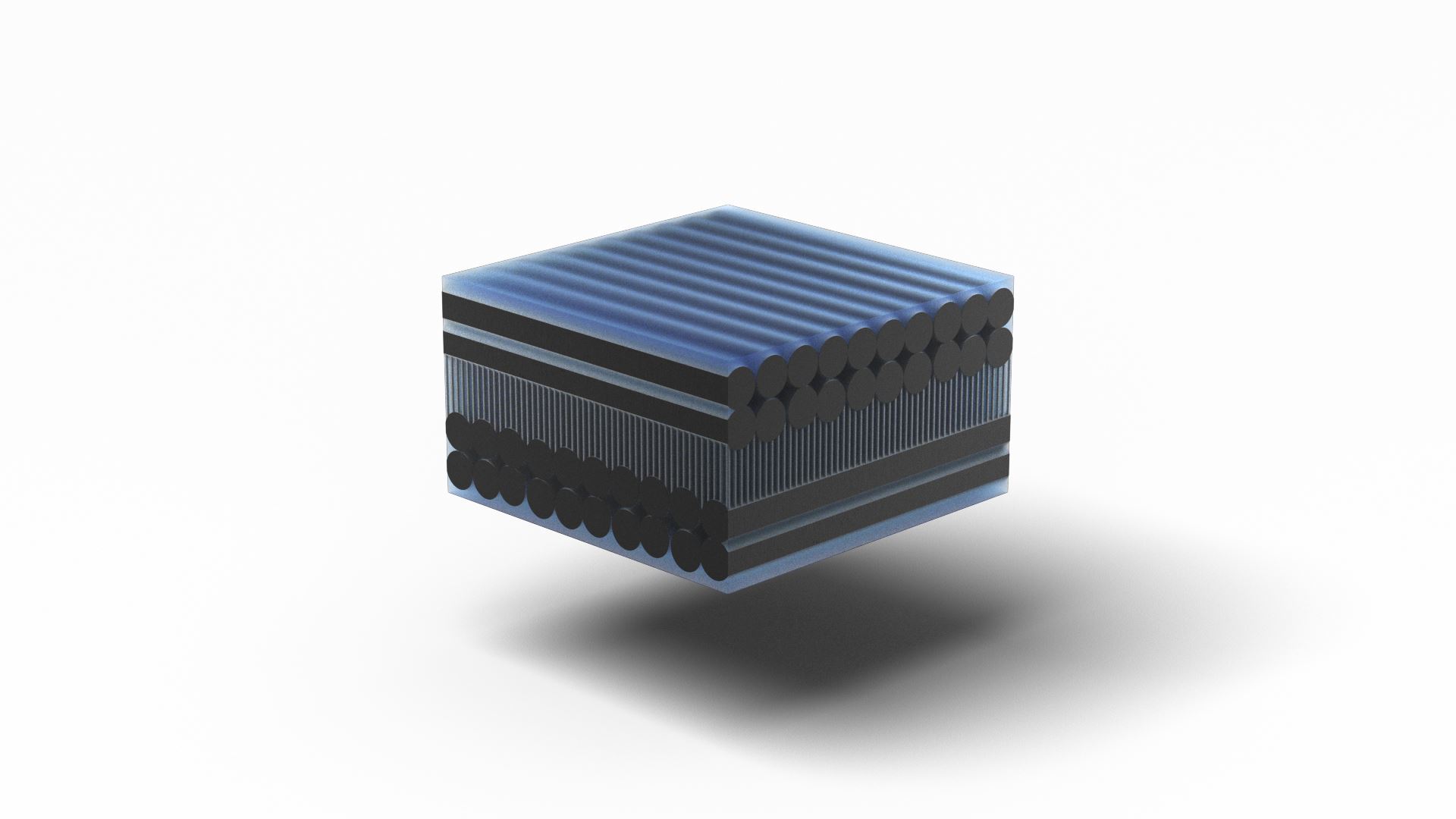

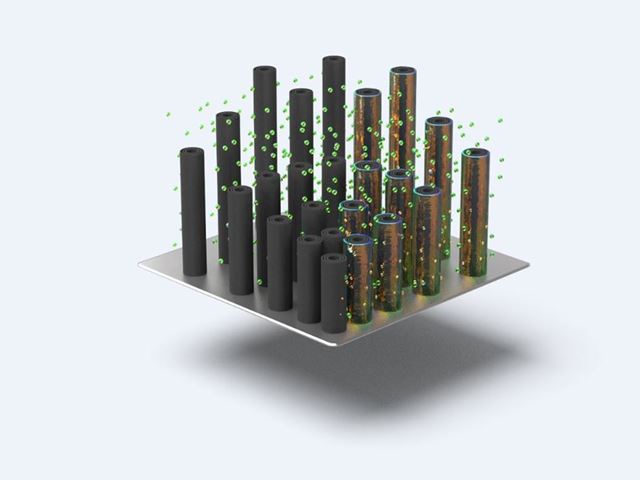

NAWA’s Vertically Aligned Carbon Nanotubes (VACNT) are the basis of all its products.

"A nanotube is a very tall, very thin column – a bit like a piece of spaghetti. Yet it is at nano scale and we arrange them vertically like a toothbrush head billions of times over, creating a carpet," says Saucier.

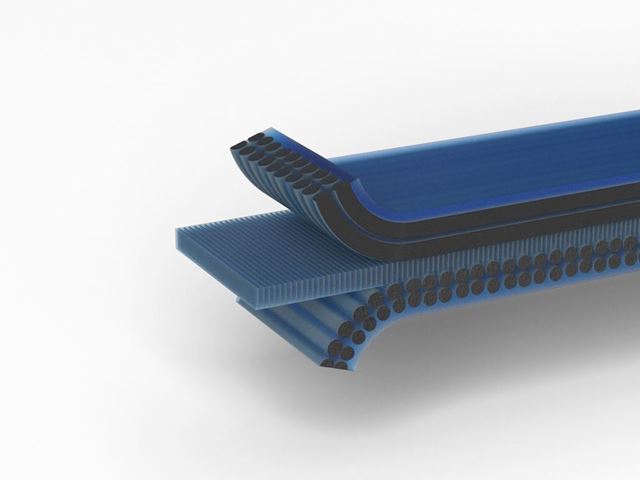

"These VACNT carpets have so many uses that we have barely scratched the surface, but one application we are using VACNT for is in advanced composites, to increase the strength of the material dramatically. This is thanks to a solution called ‘NAWAStitch’, which sees VACNT act like a ‘nano-velcro’, solving one of the biggest issues with common composites – interlaminar cracking or delamination."

NAWAStitch creates a composite with a 900% increase in impact damage tolerance, while also offering a 20-30% reduction in weight. So you get a lighter, stronger, more advanced composite, notes Saucier.

Next to composites, NAWA is also developing VACNT applications for the automotive sector.

"The nano-material’s innovative combination of greater strength combined with the heating capability when plugged to electric current can be applied to next-generation composite EV battery casings, that are not only stronger and safer, but also offer the ability to keep the battery at a constant temperature, avoiding the requirement for additional thermal management, helping to prolong the performance and life of the cells inside," he explains.

"We also see applications in the composite chassis structures of next-generation high-performance EVs, resulting in a lighter, stronger vehicle."

A Wide Range of Applications

When Saucier joined NAWA earlier this year, he set to work with the team to re-focus the business around three key areas - nano-based composite solutions, the hydrogen mobility sector and boosting EV batteries by applying nano-material to the electrode of a lithium-ion or even solid-state system.

"This technology can speed up charging times, extend range, improve safety and lifetime and will come to market before the end of this decade."

"However, these are just the examples of technology we are advancing currently, the fantastic thing about our VACNT is that there are many other sectors we can apply this innovation to. Watch this space," he adds.

In terms of hydrogen mobility, it has a range of applications.

"Because VACNT is incredibly well-organized structure at conducting electrical energy, the technology can also be used in the hydrogen fuel cell itself, dramatically boosting the performance of the platinum catalyst. We can give fuel cell manufacturers – and automotive OEMs – a choice: use less platinum or stay same and boost performance of the fuel cell, Furthermore, our technology can also dramatically extend the lifetime of a FCEV too, by a factor or five."

"Our NAWAStitch innovation can also be applied to make highly-pressurized hydrogen storage tanks stronger and lighter - up to 30% reduction in weight in fact, which is game-changing. The technological performance ‘upgrade’ really can’t be overstated when looking at the current and rather limited solutions on the market today for hydrogen storage. These limited storage solutions are one element holding back the progress of FCEVs," says Saucier.

In addition to automotive, VACNT and NAWAStitch can benefit many differing product designs from multiple industries including sporting goods, aerospace and aviation.

"Aviation and aerospace are two industries that is in the midst of rapid change and here, again, our technologies can be used to great positive effect. For example, NAWAStitch’s versatility is such that not only can VACNT be used to dramatically strengthen composites in aviation and aerospace, but the nano-material can also bring benefits in anti-icing and de-icing."

Growing Its Global Footprint

NAWA currently has two global locations, its home and headquarters in Aix-en-Provence, in the south of France, which is where its VACNT innovation was born and where mass manufacturing of VACNT for multiple applications will take place. It also has a location in Dayton, Ohio, US, which is the home of its NAWAStitch technology.

"We are in advanced talks with a number of international customers and will be striving to grow our global footprint, but for now I can’t say any more!"

Finally, we asked Saucier what transportation in Europe look like by 2030.

"It’s clear electrification is only going to accelerate, and that’s across many sectors, such as e-scooters, motorbikes, passenger cars, delivery vans and buses. Outside of automotive and commercial vehicles, there is also the electrification of the aerospace industry, with eVTOL and lighter aircraft. This will in part be driven by legislation – the phasing out of the IC engine by 2030 onwards – as well as technological progress and customer acceptance of electric vehicles," he predicts.

"Within that electrification uptake, hydrogen will play an even bigger role, most likely in heavy goods vehicles and larger commercial vehicles to start – for instance off-highway vehicles such as mining trucks – with the potential to expand into certain passenger car sectors too," concludes Saucier.

Popular Categories