- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Kia Corporation Unveils EV4 & Concept EV2 at EV Day in Spain

- Latest: Volklec Announces Plans to Open a Dedicated 10GWh UK Battery Gigafactory

- Latest: Mercedes-Benz Begins Solid-State Battery Road Tests

- Latest: BMW Unveils Sixth-Generation BMW eDrive Technology for the Neue Klasse

- Latest: Recovering Critical Battery Materials - Ace Green Recycling CEO

Developing Technologies for Next-Generation EV Batteries - Li-Metal Corp CEO Dr. Srini Godavarthy

Adrian Smith

- Jul 31 2023

Li-Metal is set to play an increasingly vital role in the electric vehicle (EV) battery supply chain in North America. Its technologies and anode materials help support battery developers in producing better, lighter, and less expensive batteries to power more cost-effective and safer EVs.

The Canadian company is currently engaged with 27 automakers and battery developers, with 15 next-generation battery developers sampling materials.

"It’s been an exciting journey so far and we are well positioned to scale a vertically integrated lithium metal and anode platform to support the development, commercialization and eventual adoption of next-generation batteries," Dr. Srini Godavarthy, Li-Metal Corp's CEO, tells Auto Futures.

Li-Metal’s vertically integrated process begins with lithium carbonate and ends with high-performance anodes ready to go into next-generation battery cells. The process utilises two core technologies: a lithium metal technology and a next-generation battery anode technology.

Driven by the development of next-generation batteries, the demand for lithium metal is expected to increase by 10 to 12 times by 2030 to more than 40,000 tonnes per year, says Dr. Godavarthy.

"Traditionally, processes that use lithium chloride generate approximately 5 tonnes of harmful chlorine gas by-product for every tonne of lithium metal produced. However, Li-Metal is able to both eliminate a costly conversion step and harmful chlorine gas emissions by producing this speciality material directly from lithium carbonate," he explains.

In May, 2023, Li-Metal's team successfully produced lithium metal directly from lithium carbonate at its facility in Markham, Ontario. This patented technology can produce the strategic material which it uses to supply its anode business.

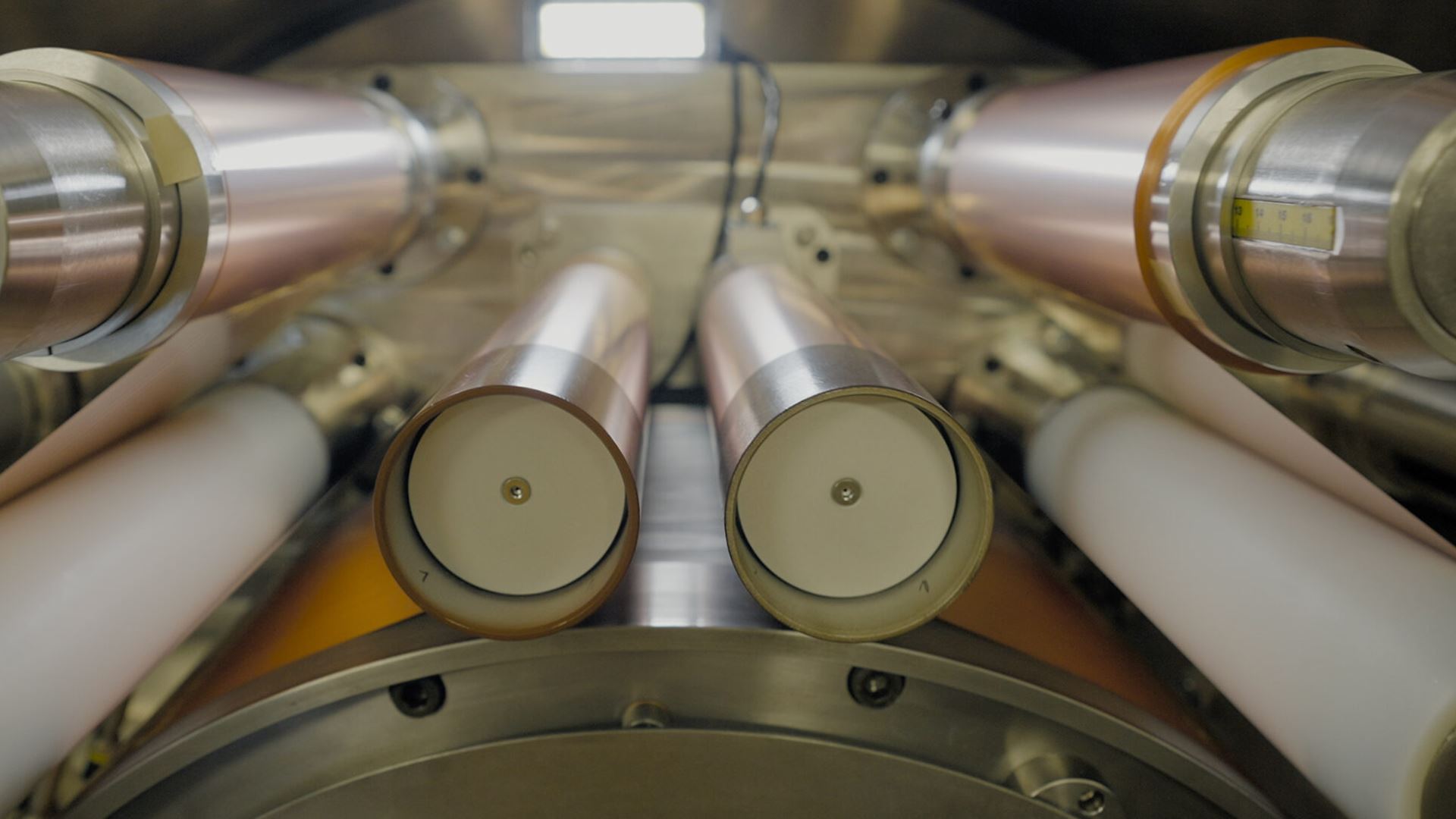

Its pilot plant in Rochester, New York, is where it produces the lithium metal anode products. The team apply vaporised lithium metal on a copper substrate to build the anode materials from the ‘bottom up’ compared to other processes which build them from the ‘top down.’

"Not only does our process allow us to minimize the amount of lithium used, it also allows us to co-deposit other materials to enhance the performance of our anode materials, as we eliminate the need for graphite in battery anodes."

The company is expanding its workforce in Rochester to help it meet accelerating customer demand for anode products.

"As we continue to advance our anode business, my short-term goal for Li-Metal is to approach 0.5 GWh of anode capacity as quickly as possible, or the equivalent of a million to a million-and-a-half of metres of anode material per year," he says.

New Lithium Metal Products

In June, 2023, Li-Metal was awarded more than CAD$1.4 million in grant funding from various programs sponsored by the Government of Ontario to develop and commercialise its lithium metal production technology. It consisted of funding from the Ontario Vehicle Innovation Network (OVIN) and the Critical Minerals Innovation Fund (CMIF).

"We plan to use the funds from OVIN (more than $900,000) to support scale-up of our production and refining capabilities for battery-grade lithium metal. We will also use these funds to advance the piloting of new lithium metal products, such as specialty lithium alloy ingots for next-generation batteries," says Dr. Godavarthy.

It plan to use funds from the CMIF to advance its lithium metal production technology.

"Scaling up our metal business helps further differentiate Li-Metal in the market as a vertically integrated domestic anode supplier and also helps advance the development of our anode business by securing a cost-effective and sustainably produced feedstock. Furthermore, we believe the funding from the government of Ontario helps further validate our technology," he notes.

Creating A Long-Lasting Supply Chain

Li-Metal is amongst a number of Canadian companies that are contributing set to North America’s broader battery ecosystem.

"We are pleased to see major players in the battery ecosystem set up shop in Canada such as Volkswagen, LG Energy Solution, Umicore and many more. Furthermore, Canada has a substantial amount of potential upstream – or the raw materials – to help create a long lasting supply chain," says Dr. Godavarthy.

The Canadian government is supporting its battery materials supply chain with a range of initiatives.

"Canada’s next-generation battery ecosystem continues to develop, and although the U.S. is where the highest concentration of next-generation battery players are located, Canada is not too far behind. As Li-Metal operates in both Canada and the US we are positioned to capitalize on the growth of their respective supply chains and the opportunities offered in both of these strategic regions."

A $40 Billion Opportunity

In the future, Li-Metal's technology looks set to help with the development of autonomous vehicles.

"Next-generation batteries will unlock the potential for several applications and create new opportunities in transportation, unlocking niches like autonomous vehicles, air taxis and electric flight. These next-generation batteries are going to redefine electrification and the way we all move around. Autonomous vehicles may be the future of the industry, but the technology needs to advance. Before being deployed in a mainstream way, the technology needs to catch up and next-generation batteries can help accelerate that."

Finally we asked Dr. Godavarthy what EV batteries and charging will look like by 2030.

"We believe that by 2030, EV batteries will be lighter and more powerful and could have increased energy density from 250-280 W-h/kg in current batteries to more than 350-400 W-h/kg. As next-generation batteries continue to progress we could have EVs on the road that are able to travel 1000 kilometers on a single charge in 2030. What will be interesting to see is which battery chemistry takes over as the replacement to the conventional lithium-ion that will be used in EVs."

"There are many promising next-generation battery technologies out there and several of them are focused on replacing graphite with a better material to increase energy density while reducing weight and volume for optimal performance and cost. However, all roads lead to ultra-thin lithium metal anodes and by 2035 the lithium metal anode market is expected to exceed $40 billion. This is because lithium metal anodes have the highest specific energy capacity of all anode materials with 10x capacity compared to traditional graphite anodes," he adds.

"We also forecast that charging infrastructure will be a lot more established in 2030. As a key enabler of better EV batteries, Li-Metal is a proponent of further driving growth of the whole next-generation battery ecosystem, which includes charging infrastructure," concludes Dr. Godavarthy.

Popular Categories