- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Kia Corporation Unveils EV4 & Concept EV2 at EV Day in Spain

- Latest: Volklec Announces Plans to Open a Dedicated 10GWh UK Battery Gigafactory

- Latest: Mercedes-Benz Begins Solid-State Battery Road Tests

- Latest: BMW Unveils Sixth-Generation BMW eDrive Technology for the Neue Klasse

- Latest: Recovering Critical Battery Materials - Ace Green Recycling CEO

The British Company Taking Electric Mobility to a new Level of Performance - YASA's Simon Odling

Adrian Smith

- Sep 17 2024

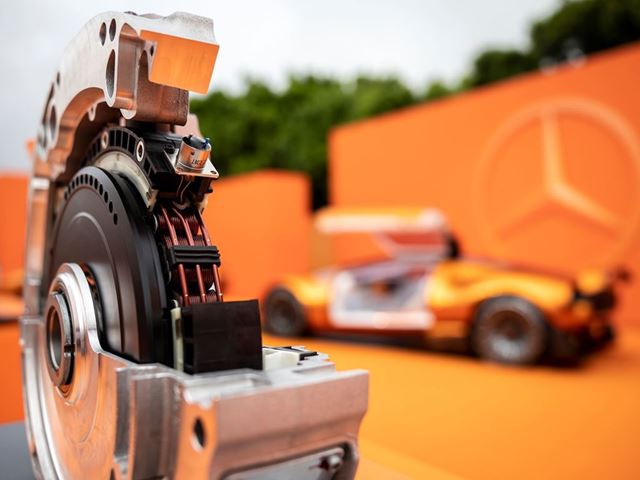

YASA is an electric motor specialist that has developed an extremely powerful and highly efficient axial-flux motor. The British company's vision is to make electric cars lighter and more sustainable.

It has been a 100-percent subsidiary of Mercedes-Benz AG since its acquisition in 2021.

"YASA’s growth reflects a trajectory aimed at enhancing performance and improving efficiency in electric vehicles, in the process aligning with global sustainability goals and reduced material use," Simon Odling, YASA's chief of new technology, tells Auto Futures.

Odling works closely with YASA's founder, Dr. Tim Woolmer, to develop new technology for the Oxford-based company.

Its axial flux technology breaks from traditional EV designs by eliminating the need for a yoke that typically binds the components of a radial flux e-motor.

"The e-motor's architecture – yokeless and segmented – optimises the use of materials like iron, copper and permanent magnets, making it incredibly lightweight yet powerful. Our electric motors can achieve higher torque at any given power level compared to radial flux motors, especially at lower RPMs," he explains.

YASA's axial flux motors are inherently more resource-efficient than radial e-motor as they use fewer raw materials. This leads to lighter vehicles and, consequently, smaller batteries or longer real-world driving ranges.

"The high efficiency of our electric motors (typically around 95-96%) means less energy waste during operation. Furthermore, our unique cooling system, which directly cools the electric motor components, allows for rapid heat dissipation, enabling high-performance use without the downtime required by radial e-motors."

In 2019, YASA announced Ferrari as its first OEM customer in volume production, with the hybrid Stradale SF90.

The company has just broken ground on a new UK HQ in Bicester, Oxfordshire.

A Technology Partnership

Mercedes-Benz, particularly through its AMG division, recognised the advantages of YASA's technology early on, leading to the acquisition in 2021.

"Our collaboration has focused on integrating our axial flux technology into AMG’s high-performance vehicles, enhancing the brand’s electric drivetrains," says Odling.

"The technology partnership extends to joint development programs, aiming to provide the power from axial flux, whilst scaling up production to incorporate our electric motors into a broader range of Mercedes vehicles, reflecting a deep, ongoing integration of our technologies," he adds.

In 2023, Mercedes-Benz unveiled the Vision One-Eleven concept car that features YASA’s axial-flux electric motors.

In a press release, Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer, states: “At the heart of the compact and extremely efficient powertrain is the innovative YASA axial-flux high-tech electric motor. It offers a motorsport-like power output from a considerably smaller package. Combined with the liquid-cooled cylindrical-cell battery with Formula-1 inspired cell chemistry, the Mercedes-Benz Vision One-Eleven is yet another proof point for the broad performance spectrum encompassed by our four-pronged development strategy for electric drive.”

Sustainable Transportation

Beyond luxury performance cars, axial flux electric motors have potential applications that can be utilised by more mainstream automotive sectors, including family vehicles and light commercial vehicles.

"The high efficiency and compact design of axial flux electric motors make them ideal for enhancing the performance and real-world driving range of electric vehicles across various categories, not just the high-end models," says Odling.

The future generation of YASA axial-flux motors will be produced at the Mercedes-Benz Berlin-Marienfelde plant in Germany.

"Looking ahead with an engineering and technology lens, YASA is focused on further optimising electric motor designs to enhance power density, reduce weight and decrease material usage. This next generation of electric motors is anticipated to significantly change the architecture of EV propulsion and its additional safety systems. Our ongoing collaboration with Mercedes and other partners is crucial to ensure we can scale our technology for broader applications in the automotive industry and beyond."

Finally we asked Odling what mobility will look like by the end of the decade.

"By 2030, the automotive landscape will be significantly shaped by advancements in electric vehicle technology. YASA’s electric motors are set to be a prominent part of this future, powering a potentially wider range of battery-electric vehicles with superior efficiency and performance," he predicts.

"We are only at the start of modern e-propulsion development, so a shift from high-end to more mainstream vehicles for technology like YASA’s will mark a significant transformation in this crucial journey, making sustainable transportation options far more prevalent in the global market," concludes Odling.

Popular Categories