- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Kia Corporation Unveils EV4 & Concept EV2 at EV Day in Spain

- Latest: Volklec Announces Plans to Open a Dedicated 10GWh UK Battery Gigafactory

- Latest: Mercedes-Benz Begins Solid-State Battery Road Tests

- Latest: BMW Unveils Sixth-Generation BMW eDrive Technology for the Neue Klasse

- Latest: Recovering Critical Battery Materials - Ace Green Recycling CEO

The UK's Bramble Energy Aims to "Revolutionise the Fuel Cell Market" - CEO, Dr Tom Mason

Adrian Smith

- Jun 19 2023

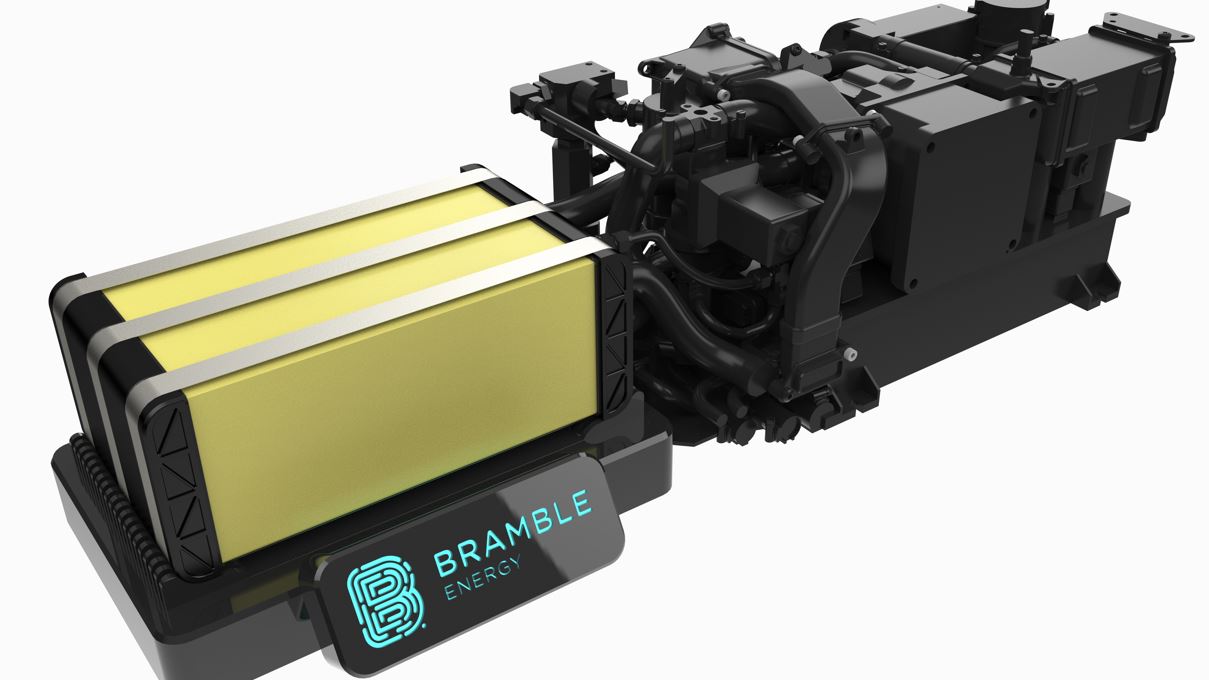

The UK's Bramble Energy was born in the labs of University College London and Imperial College London and spun out in 2016. Its radical vision is to accelerate the hydrogen mobility industry with the world's first hydrogen fuel cell built using printed circuit boards (PCBs).

"The team were working out of loaned labs on its development in 2018, and then the pandemic hit. Not affording to lose time, we packed up all our equipment in one day and took it to my garage to carry on testing our technology. We secured significant funding in 2020 and have seen huge growth since," Dr Tom Mason, Bramble Energy's CEO, tells Auto Futures.

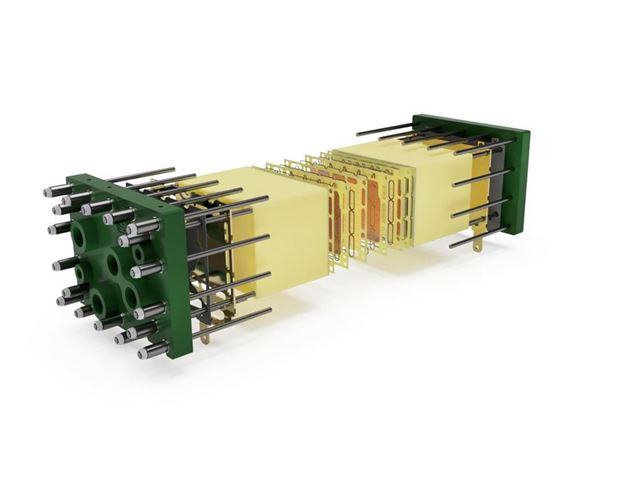

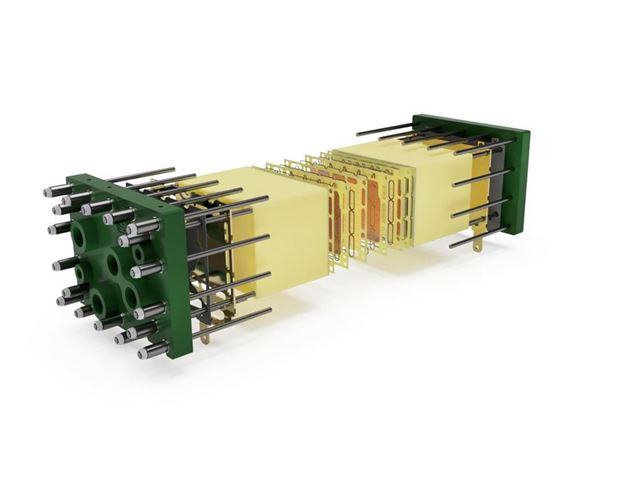

Bramble’s Printed Circuit Board Fuel Cell (PCBFC) is based on its PCB-X technology. It utilises innovative manufacturing processes to create fuel cell stacks in almost any size and arrangement. Thanks to its lower material, production, and manufacturing costs, the technology is much cheaper compared to traditional fuel cell stacks.

"The solution uses far fewer components, which makes it both cost effective and flexible. Fuel cell components are currently produced at a relatively small scale and use expensive metals in the catalyst – Bramble’s solution doesn’t," says Mason.

The company says it can design, manufacture, test, and deliver a fuel cell stack in a matter of days. The patent protected fuel cells can also be manufactured in most PCB factories worldwide.

"PCBFC™ technology has the potential to revolutionise the fuel cell market and accelerate the shift towards hydrogen for automotive, marine, aviation, and energy storage. It can do this as the technology can overcome major challenges that face the hydrogen industry – cost, speed to manufacture, scalability."

A Hydrogen Bus Project Named HEIDI

Mason believes that hydrogen will revolutionise heavy duty transport, as battery electric technology faces a number of challenges when scaling up to vehicles such as HGVs. This is because the batteries required to deliver realistic ranges at high-power demands would be extremely heavy, and the charging time for HGVs is longer than for smaller, lighter vehicles.

"Hydrogen fuel cells can offer vehicles such HGVs, and marine applications, greater range, higher load carrying capacity and quick refuelling without putting strain upon the local electricity grid," he explains.

"It is important to remember that it is not a battle between hydrogen vs battery, but about what technology is best suited to decarbonise the required application. As hydrogen refuelling infrastructure becomes more widely available, hydrogen vehicles of all sizes will become more attractive due to the quick refuelling times."

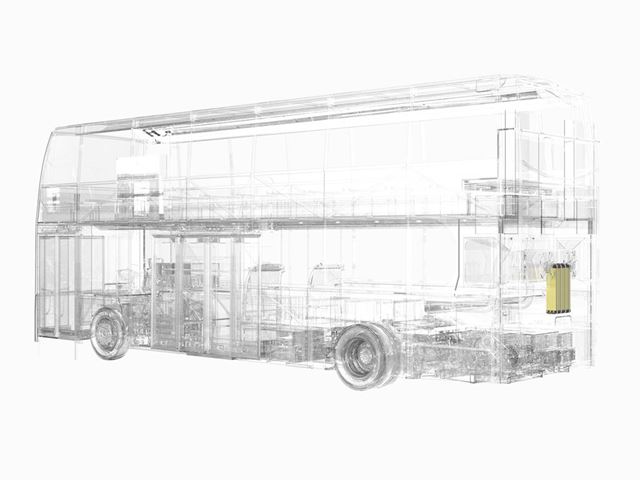

Bramble Energy was recently awarded funding from the UK Government to lead a consortium for a hydrogen bus project called HEIDI (Hydrogen Electric Integrated Drivetrain Initiative). The UK-based consortium will develop a hydrogen-powered double-deck bus, using PCB-X technology.

"Bramble will be designing and supplying the integrated fuel cell stack for the bus. Others in the consortium include Equipmake, Aeristech and the University of Bath. Bramble Energy has been selected for this project due to its revolutionised fuel cell design and manufacturing process," says Mason.

The consortium will also support fuel cell manufacturing in the UK for buses and commercial vehicles.

"The bus sector is one that needs to rapidly decarbonise, hydrogen is the most viable solution to do this. Battery electric buses require building very large batteries that need a lot of energy from the grid to charge, which also takes the bus out of service as part of this lengthy downtime. The grid capacity to run a fleet of fully electric buses would require substations built at much cost to cope with the demand for energy."

The HEIDI project is projected to not only support almost 500 jobs over the next ten years, but also provide CO2 savings of 5.9m tonnes.

The Road to Net Zero

PCBFC technology can be used for different types of transportation

"Applications can be wide but the best suited to fuel cell technology can range from LCVs, HGVs, buses, and marine applications. We have even created the first fuel cell powered remote controlled car," says Mason.

He believes that hydrogen-powered mobility can play a key role in helping the UK achieve Net Zero

"Now that people realise they can pivot to hydrogen without the high cost, over the next 10 years more investment and interest in hydrogen will see it become a major part of the zero-emission solution."

"Net Zero targets are a challenge across all industries but we’re seeing the realisation that one energy technology cannot solve all. Batteries will improve but they are not a silver bullet. It will take a combination of multi-energy solutions," he adds.

Finally, we asked Mason what road transportation will look like by 2030,

"It’s no surprise to anyone that by 2030, road transport will be in a far more sustainable position, facilitated by the development, evolution and uptake of green alternatives to internal combustion engines (ICE)."

"Through a mixture of growing technologies, such as hydrogen and battery powered vehicles, we will have moved ever closer to zero-emission transport and mobility. Therefore, what we’ll see is a healthy variety in the technologies that underpin our road transport, with ever-increasing numbers of hydrogen powered HGVs and EVs for example," concludes Mason.

Popular Categories