- Latest: Welcome to Auto Futures - Mobility News, Features, Exclusives and More...

- Latest: Kia Corporation Unveils EV4 & Concept EV2 at EV Day in Spain

- Latest: Volklec Announces Plans to Open a Dedicated 10GWh UK Battery Gigafactory

- Latest: Mercedes-Benz Begins Solid-State Battery Road Tests

- Latest: BMW Unveils Sixth-Generation BMW eDrive Technology for the Neue Klasse

- Latest: Recovering Critical Battery Materials - Ace Green Recycling CEO

"They're Going to go Bankrupt" – IONETIC CEO on Helping Electrify Britain's Niche Automakers

For automakers, switching to electric powertrains isn't always straightforward and it is never cheap.

While huge conglomerates such as Volkswagen and General Motors can throw money at the problem of electrifying, not all car manufacturers are so fortunate. The British automotive market is dominated by a range of niche players ranging from high-performance manufacturers such as Ariel and BAC to companies that produce buses and vans for export all over the world.

For these smaller companies, switching to electric propulsion can seem impossible. However, battery pack manufacturer IONETIC believes that it has developed a platform to make the switch easy, fast, and, most importantly, affordable. We spoke to James Eaton, CEO and co-founder to find out more.

Double the Volume, Half the Cost

"The company essentially came to be when I was working with industry partners [at Imperial College London]. At that point, I had two years in battery pack development and research but I was the expert in the room," explains Eaton.

"All these guys had been working in the automotive sector for 20 years or more, but all in combustion. Their battery pack knowledge wasn't so great because it was such a new industry."

It was from here that Eaton, along with Dr. Monica Marinescu, who still lectures at Imperial in the Department of Mechanical Engineering, founded IONETIC.

"We started the company as a consultancy," explains Eaton.

"We were going to just do specific projects for companies designing full battery packs or helping to improve their existing systems. We spoke to a lot of car companies, and primarily niche car companies, and they all had the same problem."

Eaton, speaking to us over a video call from Cenex LCV, a UK trade show dedicated to low-carbon and fuel cell transportation, says that these companies were faced with three insurmountable problems. The battery packs on offer were either too expensive, the companies couldn't get a supply of the battery packs, or the engineering of the packs wasn't good enough.

"We sat down and thought, 'We should solve this problem.' You know, big car companies can't even electrify themselves, they're going to go bankrupt," Eaton says.

"The first thing we did was realise that you have to design and manufacture, you can't just do design. You can't simply develop this great product and hand it to a small car company. Fundamentally, it's just a black box to them and they're expected to somehow make it.

"The second thing that we realised was that we needed to stop redesigning everything because that's all the consultants do. That's their business model and it makes sense. If you want 100% perfect maximum optimisation, everything just for you, go to a consultancy and spend tens of millions and you'll get that."

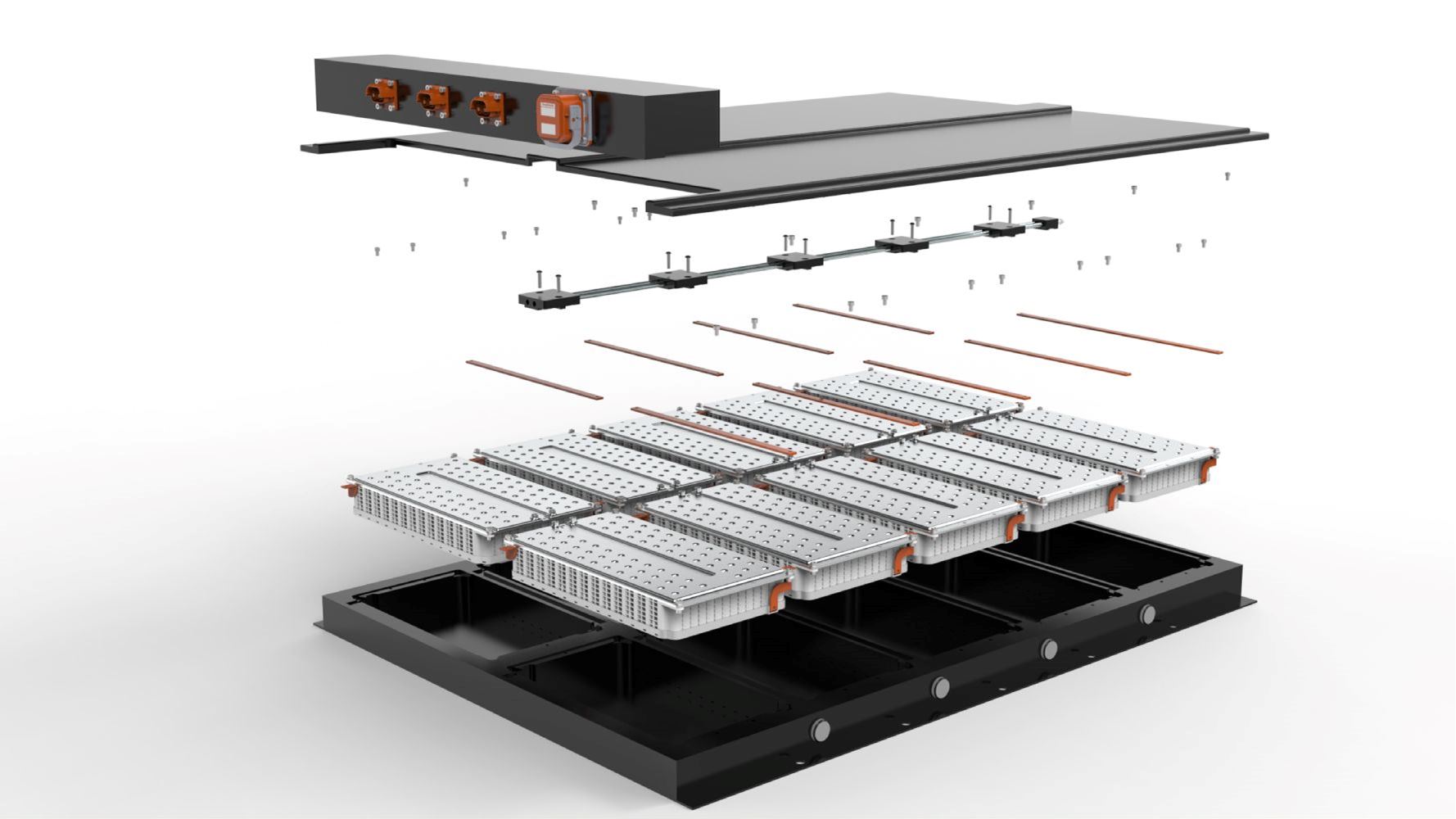

IONETIC, however, starts with a standard battery pack and modifies it with each company before manufacturing it. That means each battery pack is not a completely bespoke unit. Components, materials, and elements of designs are shared between manufacturers. But this means that costs can be reduced by more than 90% while the utilisation of pack volume grows by 120%.

Working Smarter, Not Harder

Compared to VDA modules, a widely used and industry-standard battery pack, Eaton explains that IONETIC's approach has significant benefits for low-volume manufacturers.

"On energy density, it's because we customise for the customer. If you look at a VDA module, they're very small. That means you're carrying around a lot of structural weight just to ho,d the batteries in a box. Our modules, we try to make them as big as possible, which means that we're carrying as little structural weight as possible," he explains.

"But also, because we have control of the manufacturing and the whole system, we can optimise everything. So battery pack casings, we can make sure we make them as lightweight as possible but keep them safe and structural. We can make sure the control system is as lean as it can be. Basically, by optimising the solution, we can improve the density."

The most important savings for IONETIC's typical niche manufacturer clients are cost savings.

"In terms of cost, part of it is the optimisation and the ability to automatically design a solution and the platform — that's what brings the cost down a lot in production," he continues.

"But other things that bring the cost down are that we will have a factory when we put these into production. Pilot production starts next year, so that means you [the automaker] don't need to open a factory, you don't need to spend £40 million on a battery pack factory. We can distribute the cost across all our customer base, which means the actual cost you're exposed to as a customer is very small."

Plus, IONETIC will offer regulation 100 testing, a crucial step for getting cars homologated for road use in the UK, as well as managing the supply chain, further removing cost and risk for niche automakers.

A Challenging Outlook?

However, while IONETIC certainly isn't short on companies that will want to electrify their vehicles for affordable prices, the economic outlook of the UK is relatively gloomy.

Energy prices are rising and consumers are seeing their energy bills double in the space of a year. Now might not be the best time for many to purchase a new two-seat sports car for Sunday spins.

Of course, the commercial vehicle sector will have to electrify — by the end of the decade, new petrol and diesel-powered cars in Britain will be removed from sale. However, the challenges are far from over with ongoing supply chain issues and the new British government receiving some interesting cabinet appointments.

"Anyone who isn't worried about energy prices is probably not looking at the market," says Eaton.

"We're a bit less exposed to it that, let's say, cell manufacturers because it's a less energy-intensive process getting from cell to module to pack. But, obviously, the more their costs increase, the more our bill of materials goes up and it does have an impact on us. We've got some mitigation strategies, we're considering what we can do to reduce our exposure to the energy market, whether it's grid storage solutions or solar panels and those kinds of things.

"In terms of our supply chain, we want as much of that to be in Europe as possible. How much that's possible, considering what exists in Europe, I'm not sure. But we're talking to people all the time. I was literally just having a meeting before this about how we bring some supply chain stuff to Europe."

Eaton does seem more confident about the political situation, however.

"I think there are a few things to say. Whether you agree with any other policy, the British government's support of the battery sector, in general, has been very, very positive in the last few years. Look at Innovate UK grants or the Advanced Propulsion Centre and there are lots of ways that the government is supporting battery development.

"The second thing is that demand is so high now that I think, irrespective of government support, electric has outgrown every other vehicle sector for quite a few quarters now. Obviously, I hope that the government continues to support battery pack, module, and cell development and the materials supply chain all the way — but I don't think it's mission-critical at this point.

"In terms of ministerial appointments, it is what it is and whether I comment on it or not will not change the outcome."

IONETIC's solution certainly seems to be the perfect fit for the low-volume British car industry. Plus, with the market, while slowing, inexorably heading towards battery-electric powertrains, it seems that IONETIC might have timed it right, as well.